OVERVIEW

TABLA DE COMPARACION

This overview compares the different options to connect a Lambda sensor to an ECU or data logger.

| Lambda Upgrades | PLM | LTC LTCD | ||||

|---|---|---|---|---|---|---|

| Single upgrade | Dual upgrade | Compatible technology | Connect using PLM output signal | Connect using PLM on CAN (multiple PLMs) | ||

| Data loggers | ||||||

| EDL3 – Obsolete |  |  |  |  |  | |

| ACL – Obsolete |  |  |  |  |  | |

| D153 |  |  |  |  |  | |

| D175 |  |  |  |  |  | |

| C125 |  |  |  |  |  | |

| C127 |  |  |  |  |  | |

| C1212 |  |  |  |  |  | |

| C185 |  |  |  |  |  | |

| C187 |  |  |  |  |  | |

| C1812 |  |  |  |  |  | |

| L120 |  |  |  |  |  | |

| L120 (USB) |  |  |  |  |  | |

| L180 (USB) |  |  |  |  |  | |

| ECUs | ||||||

| M400 – Obsolete |  |  | 5 Wire |  |  |  |

| M600 – Obsolete |  |  | 5 Wire |  |  |  |

| M800 – Obsolete |  |  | 5 Wire |  |  |  |

| M880 – Obsolete |  |  | 5 Wire |  |  |  |

| M122 |  |  |  |  |  | |

| M130 |  |  |  |  |  | |

| M141 |  |  |  |  |  | |

| M142 |  |  |  |  |  | |

| M150 |  |  |  |  |  | |

| M170 |  |  |  |  |  | |

| M181 |  |  |  |  |  | |

| M182 |  |  |  |  |  | |

| M190 |  |  |  |  |  | |

DIRECTORIO

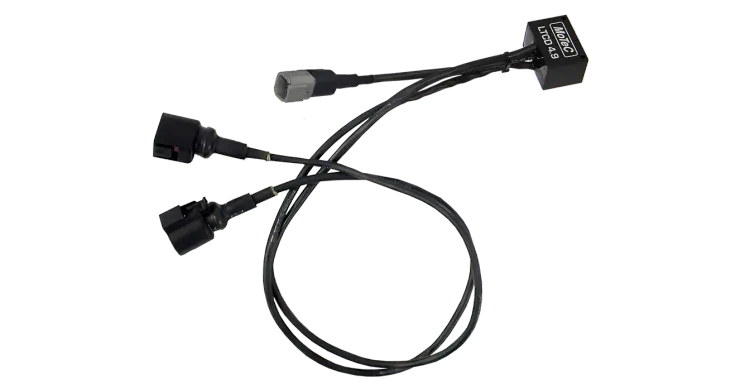

LTCD

Part No: #61301

Lambda To CAN Dual module

LTCD (LONG)

Part No: #61301L

Lambda To CAN Dual module

Long Loom

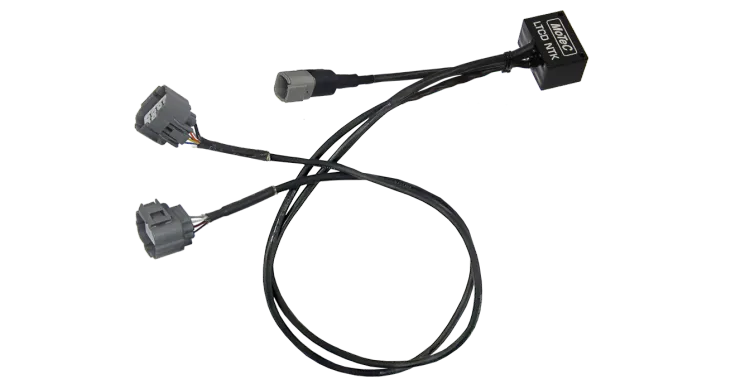

LTC NTK

Part No: #61304

Lambda To CAN module

LTCD NTK

Part No: #61305

Lambda To CAN Dual module

LTCD NTK (LONG)

Part No: #61305L

Lambda To CAN Dual module

Long Loom

PLM

Part No: #15004

Professional Lambda Meter

EXPLICACION

What is Lambda?

Lambda is a measure for the mass air to fuel ratio (AFR) present during combustion. When exactly enough fuel is combined with the available free oxygen, the mixture is chemically balanced and is called stoichiometric.

- Lambda = 1 —stoichiometric mixture

- Lambda < 1 —mixture is rich, excess fuel present

- Lambda > 1 —mixture is lean, excess air present

The amount of air that is needed depends on the type of fuel used. In the case of gasoline/petrol, a stoichiometric mixture consists of an air to fuel ratio of 14.7 to 1. For different fuel, different ratios apply.

Narrowband Lambda

Narrowband Lambda is a measurement method where the AFR range is limited from 14:1 to 15.4:1. The sensor reading switches very sharply between the thresholds of lean and rich areas, providing a signal which indicates either a rich or a lean mixture but not to what degree.

This works well in controlling an engine for emissions, however, the limited range makes narrowband Lambda unsuitable for accurate tuning.

Wideband Lambda

Wideband Lambda sensors are designed to give an exact reading of Lambda. This is particularly useful when the precise mixture needs to be known in order to tune the engine for optimum power. The measuring range can span from 0.7 to 32 Lambda for a 5 wire sensor type.

Wideband Lambda sensors use sophisticated controls, as the temperature change needs to be taken into account to be accurate.

There are two concepts for measuring wideband Lambda:

4 Wire Wideband Lambda Sensor

This technology takes advantage of the fact that the sensor’s voltage output is based on not only the oxygen differential between the exhaust pipe and atmosphere, but also on the temperature of the sensor itself. Sensor impedance varies with temperature, so not only the sensor voltage, but also the sensor impedance needs to be measured. Systems which do not use at least four wires typically have errors in displayed Lambda as high as 8 percent!

5 Wire Wideband Lambda Sensor

This newer technology determines the air fuel ratio of an engine by measuring Lambda sensor voltage output and the current required to hold the sensor voltage output constant. This method offers increased speed and accuracy over the older 4 wire sensor technology.

Tuning with Lambda

The tuning objective dictates the target Lambda. Typical gasoline/petrol engines produce

- peak power at Lambda between 0.84 and 0.90

- best economy at Lambda equal to 1.05

- optimal emissions at Lambda slightly lower than 1

MoTeC ECUs allow for a Lambda goal table based on load and RPM.

Referencing the measured Lambda, the Quick Lambda function in the software adjusts the values in the fuel control table at the specified load and RPM site to achieve the goal Lambda.

Similarly, the Lambda Was function adjusts the values in the fuel control table using recorded Lambda measurements from a data log.

QUE ESCOJER

There are three factors to consider when choosing Lambda measurement equipment:

Purpose

- Narrowband Lambda measurement for emission control

- Wideband Lambda measurement for accurate tuning

Lambda Sensor

- Narrowband—Ford

- 5 wire wideband—Bosch LSU

- 5 wire wideband—NTK UEGO

Models

- LTC /LTCD

The Bosch LSU 4.9 Wideband Lambda sensors can be connected to an LTC or LTCD unit to transmit the values on CAN. The LTC is the singular version that connects to one Lambda sensor, while the LTCD, the dual version, connects to two Lambda sensors.

Up to 32 Lambda sensors can be connected on the one CAN bus using numerous LTCs, LTCDs or a combination of both. They are compatible with any current MoTeC Dash, Logger, ‘hundred series’ or M1 ECU. The can also be used (in conjunction with a UTC) as a standalone solution with a PC, for example on a dyno. - PLM

Wideband Lambda sensors can be connected to the PLM—a stand-alone Lambda meter with integrated display—which transmits the data via an analogue voltage output or via CAN communications. The PLM uses the 5 wire sensor technology.

The PLM can be used to connect a 5 wire technology sensor into an ADL3, SDL3, ACL using the CAN Bus. or earlier generation ECU through an AV input.

On the data loggers, ‘hundred series’ and M1 ECUs the number of Lambda measurement inputs can be extended by connecting multiple PLMs to the CAN bus. - Lambda Upgrades

Wideband Lambda sensors can be directly connected to an ECU omitting the need for an external Lambda amplifier. This requires the wideband Lambda upgrade to be enabled in the device.

— the ‘hundred series’ ECUs are capable of using 5 wire sensor technology

— the earlier generation ECUs use the 4 wire sensor technology