OVERVIEW

EV DESIGN AND DEVELOPMENT MADE EASY

Driving «EV»olution

MoTeC is committed to contributing to future intelligent electric race cars and transportation solutions. Our proven expertise is built on 30 years’ experience in developing specialist automotive electronics and control systems for motorsport and commercial applications.

MoTeC has a wide range of product types and models that can be used in enabling and integrating an EV system design. MoTeC’s advanced programing and calibration tools facilitate the design and development phases and speed up the testing and validation process.

VISTA GENERAL

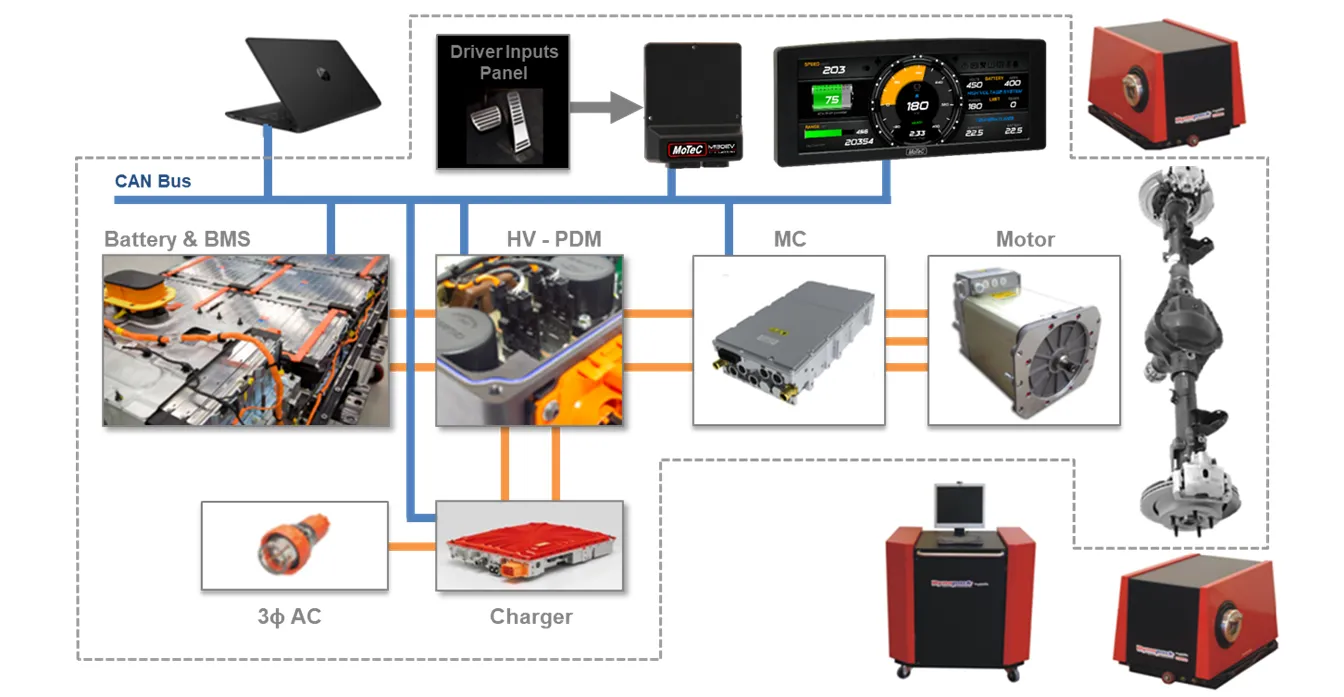

MoTeC products and software tools provide a modular, dynamic platform to design and develop integrated control solutions for Electric and Hybrid vehicle applications. All MoTeC hardware and software products can be utilised in the design and development of EV solutions, including:

Hardware

- M1 Series Vehicle Control Units (VCUs)

- PDMs as LV distribution units

- Displays as an effective Human-Machine Interface (HMI) for efficient communication to the driver

- Logging Devices

Software

- M1 Tune

- M1 Build

- Simulink Integration Tool

- Data Analysis Software

Engineering Services

Are you looking for technical consultancy on your EV project? MoTeC provides various engineering services to EV and Hybrid projects. For more information go to the Engineering Services tab.

SOLUCIONES

@olsbergsmse, @qev_tech, @nitrorallycross

All MoTeC hardware and software products can be used in the design and development of EV solutions. The main MoTeC product lines and those being applied to EV solutions include: M1 Series Vehicle Control Units (VCUs), PDMs as LV distribution units and Displays as an Human-Machine Interface (HMI) for communication to the driver.

DIRECTORIO

M1 – VEHICLE CONTROL UNIT (VCU)

Innovation Driving Performance

- MoTeC M1 VCUs deliver an exciting new era of EV control capability. Unique M1 technology redefines the potential for customisation using MoTeC’s M1 Build and M1 Tune software.

- M1 VCUs are also suitable for HEV applications, with the ability to control modern internal combustion engines, Drive by Wire, variable cam control and sequential gearboxes.

- Advanced, multi-level security makes the M1 VCU a highly flexible solution for both category management and custom implementations that require authorised VCU access.

M1 Series VCUs Highlights

- Latest generation high-performance processor

- Extremely compact and lightweight

- Large logging memory with Ethernet for fast downloads

- Compatible with 12 V and 24 V systems

- Multiple High Side and Low Side outputs with PWM capability, fully programmable in software

- Multiple Digital, PWM, Analogue and Temperature inputs, fully programmable in software with diagnostics

- Multiple communication ports (CAN, RS232 and LIN)

- Flexible programming and calibration tools (M1 Build and M1 Tune)

- Simulink Enabled for model-based programming

- Suitable for electric cars, electric bikes, electric boats and custom vehicles

COLOUR DISPLAY LOGGER

Innovation Driving Performance

- High contrast LCD screen with full sunlight clarity

- Available in screen size variants of 5 inch, 7 inch and 12 inch

- Multiple CAN buses and I/Os suitable for EV applications

Fully customisable using MoTeC’s GUI MS Windows software for EV applications

- Multiple dedicated EV screen layouts

- Data logging capabilities with on-board maths and logic function processing

- Versatile and configurable alternative to traditional instrument clusters

POWER MANAGEMENT (PDM)

LV Power Distribution Module

- Programmable LV power distribution modules, fully customisable

- PDMs provide electronically switched power to a vehicle’s electrical systems and components, including LV motors, lights, solenoids and devices such as ECUs

- Multiple CAN controlled I/Os suitable for EV applications

- Full diagnostics, output current sensing plus over-current, short circuit, thermal overload, reverse battery and load dump protection

L-SERIES LOGGERS

- The L-Series Enclosed Loggers are powerful control devices and fully programmable data loggers with a USB logging option, that can be used in a range of EV applications depending upon which options are enabled.

- They can be used as a controller for any MoTeC D-Series Display, forwarding all required channels to the Display, including lap timing, CAN and RS232 channels and much more.

- They can be placed anywhere in the vehicle and log any CAN and RS232 bus, as well as inputs wired directly to the box.

- As an optional upgrade, T2 Telemetry can receive messages from other CAN units, convert it to a T2 data stream and transmit to the radio for the pit side T2 system.

M1 BUILD

Programming Platform

M1 Build is an IDE (Integrated Development Environment) which is used to generate MoTeC’s M1 VCU Control Packages. M1 Build enables customers to develop solutions, both simple and complex, including making modifications to existing projects to meet specific needs.

M1 INTEGRATION TOOL

For use with Simulink®

MoTeC M1 Integration Tool, for use with Simulink® enables the integration of a compiled Simulink® model into an M1 control unit. This feature provides a streamlined pathway from MATLAB® and Simulink® control system development to embedded software for an M1 controller by providing a dedicated MoTeC target to the Simulink® Code Generation.

The M1 Integration Tool is installed in MATLAB® and Simulink® and makes MoTeC custom blocks available through the Simulink® library browser. These custom blocks may be used when developing the model. Compilation of the Simulink® model generates a User Library that can be used within M1 firmware development to assign channels and connect physical I/Os.

Features

- Intended for firmware development for MoTeC’s M1 ECUs, designed for motorsport.

- Suitable for development of petrol and diesel engine management systems.

- Suitable for development of Electric Vehicle and Hybrid Electric Vehicles applications.

- Enables ECU configuration, analysis and calibration using MoTeC’s M1 Tune software.

- Allows data visualisation and analysis using MoTeC’s i2 software.

M1 TUNE

Calibration Platform

M1 Tune software provides the link between the M1 Package and the M1 VCU. M1 Tune is used for the configuration, analysis and calibration of M1 firmware. The application allows users to create custom screen layouts that make EV drivetrain calibration faster and easier.

i2

Data Analysis Software

MoTeC’s i2 data visualisation and analysis software has been developed for the use of professional race teams worldwide. It enables comprehensive analysis of logged data using various graphics and maths functions for custom data processing. i2 software has a user friendly graphical interface, with the ability to set up multiple worksheets within a project. The combination of i2 and M1 Tune software provides an effective platform for EV developers to analyse test data and implement optimisation algorithms to improve their EV control solution.

SERVICIOS DE INGENERIA

MoTeC provides comprehensive EV/HEV Engineering Services, tailored to each client’s needs. Our team of EV experts take a goal-oriented approach and work collaboratively to design and develop EV control solutions that speed up and simplify the testing and validation process for the clients.

Our services include:

- Defining the required drivetrain power and battery energy;

- Recommending suitable HV subsystems for the project such as motor, inverter, battery pack and so on;

- Designing a customised HV Power Distribution Unit; and

- Providing programming services to design and develop the customised EV supervisory controller.

For more technical information on M1 VCUs as the master supervisory controller, please refer to our Electric Vehicle Application Note.

MoTeC’s EV test bench in Melbourne is built with the purpose of facilitating the EV design and development process by providing a platform for testing and performance validation of the full EV drivetrain on the dyno prior to any system set up in the vehicle.

For more technical information on M1 VCUs as the master supervisory controller, please refer to our Electric Vehicle Application Note.

MoTeC’s EV test bench in Melbourne is built with the purpose of facilitating the EV design and development process by providing a platform for testing and performance validation of the full EV drivetrain on the dyno prior to any system set up in the vehicle.

There are three main approaches to engaging with MoTeC and utilising MoTeC products for EV applications, in particular using the M1 VCUs, these being:

- MoTeC provides technical support and training on the MoTeC products and software development environment (if needed); while the client develops the full EV solution, including all M1 ECU supervisory controllers programming.

- The client and MoTeC collaborate on the development of the required EV control solution.

- MoTeC develops the EV integration and control solution for the client in accordance with a client-defined system specification.

Please contact MoTeC to discuss your EV project requirements, including technical guidance on how MoTeC products can enable your EV application solution.

Sensores de presión – Fluidos

TI Pressure Sensor

500 PSIA (3446 kPa)

(–15 to 485 psi g)

1/8 npt

Part No: #58033

Honeywell MLH Pressure Sensor – 100 PSI (689 kPa)

Part No: #58041

Honeywell Pressure Sensor- 250 PSI

Part No: #58042

Honeywell MLH Pressure Sensor- 2000 PSI (13785 kPa)

Part No: #58043

Honeywell Pressure Sensor – 5000 PSI

Part No: #58044

Pressure Sensor

Connector Kit

Part No: #65013