IGNITION SYSTEMS

VISION GENERAL

How to Choose

To decide which products to use for your ignition system consider the following factors:

Trigger System

The ignition timing is triggered by the engine position. A Ref signal indicating crank shaft position and a Sync signal indicating camshaft position (optional) provide this information to the ECU. Many different types of trigger sensors may be used. These signals can be derived from the OEM system or by using MoTeC’s trigger wheels and crank and cam sensors.

ECU

The ECU calculates the engine position from these Ref/Sync signals, and applies the appropriate ignition timing. The number of ignition output signals needed in a particular application depends on the engine (number of cylinders) and the ignition mode. If the number of ignition outputs available on the ECU is not sufficient, this can be increased by using a MoTeC IEX.

Inductive Ignition versus CDI Systems

In an inductive ignition system, the coil is charged at battery voltage for a period of time—known as ‘dwell time’—prior to firing. The dwell or charge time is controlled by the ECU and should match the coil being used in order to not over or under charge. Undercharging reduces available spark energy, while overcharging can cause overheating of the coil and/or ignition module. Inductive ignition systems produce a spark, at a lower voltage with a longer duration compared to capacitor discharge ignition systems.

A CDI, Capacitor Discharge Ignition system is charging constantly and sends a large voltage charge (380–450 V) to the coil. The spark produced is extremely short in duration and at a much higher voltage than an inductive setup. Note that inductive coils should not be used with a CDI system; CDI compatible coils are required.

There are three main engine running characteristics to consider:

- High cylinder pressures: Generally, higher cylinder pressures require more voltage to initiate a spark. Boosted or nitrous injected engines create tremendous cylinder pressures that increase resistance to lighting the ignition spark. CDI systems are most often used on these engines.

- High RPM: The time available to charge the coil in an inductive system reduces at higher RPM. If the time available is shorter than the time required for a full charge, coil power and, as a result, performance will be reduced. A CDI system might be required.

- Lean mixtures: The shorter spark duration in CDI systems might not be sufficient to ignite enough of the mixture to propagate the flame front through the cylinder. Inductive ignition will perform better in this setup.

Most vehicles, including high performance road and race applications use an inductive ignition system. Generally, if your engine can run correctly on an inductive setup, it is better to leave it that way and install a CDI system only when your engine, due to high RPM or cylinder pressure, requires that you do so.

Charging the Coils

The ignition signal is provided to the ignition module that controls the coil. Choose either inductive or capacitive discharge ignition modules with the correct number of channels.

Distributor

Depending on the ignition mode your application might need a distributor to deliver the spark to the relevant cylinder.

Ignition Coils

Depending on your system, choose either inductive or capacitive discharge ignition coils.

INDUCTIVE IGNITION MODELOS

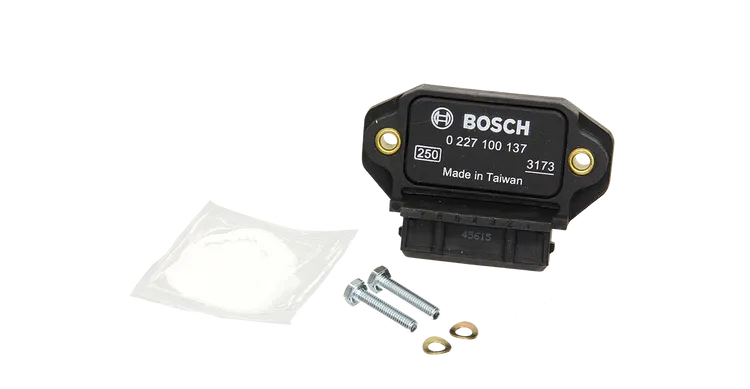

124 – single channel ignition module

Part No: #41124

200 – dual channel ignition module

Part No: #41200

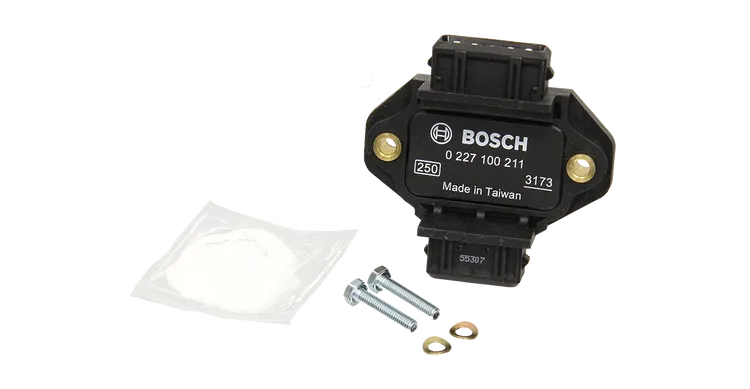

211 – four channel ignition module

Part No: #41211

IGN4 Ignition Module

4 Channel

Part No: #41212

7 Pin Bosch Ignition Module

Connector Kit

Part No: #65010

4 Pin Connector Kit

fits 209 / 211 Module

Part No: #65021

5 Pin Connector

fits 211 Module

Part No: #65023

4 Pin Connector

fits Denso Coil #42015

Part No: #67011

7 Pin Ignition Module Boot

Part No: #67008

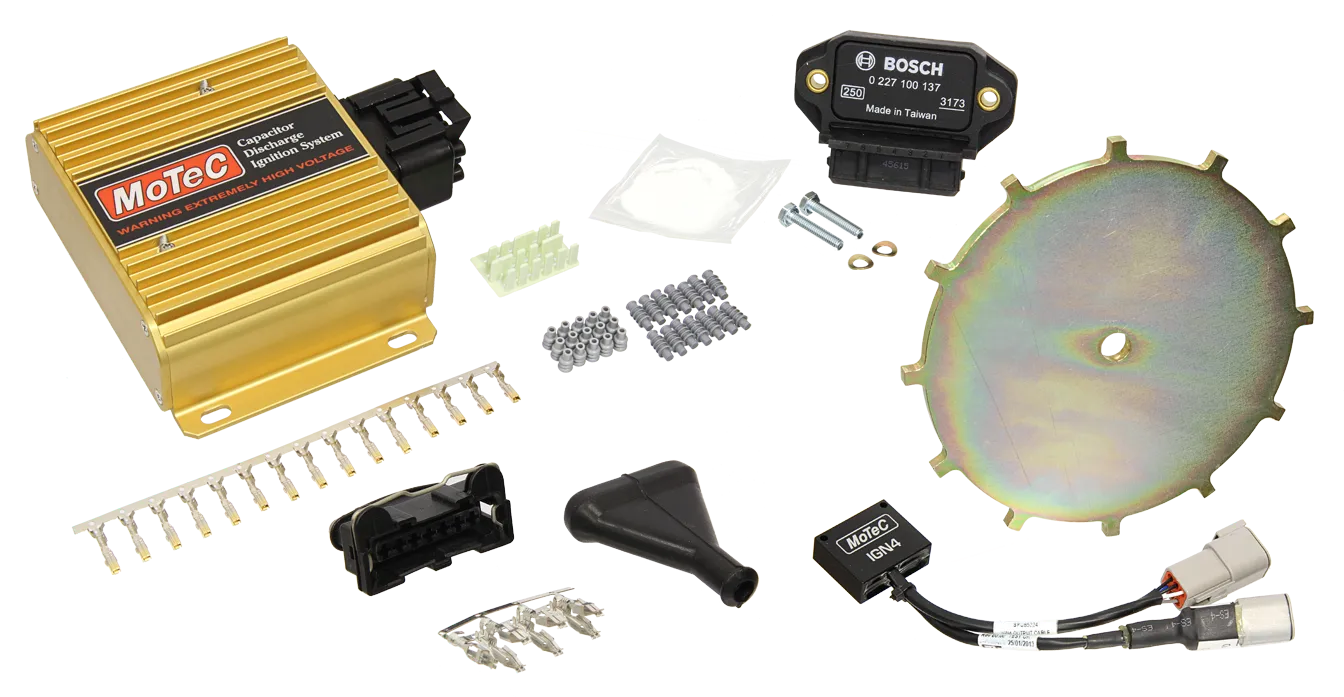

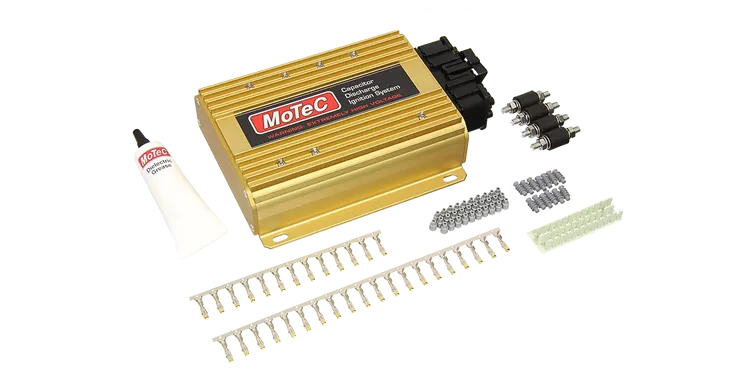

CDI MODULES

CDI-8

Designed to drive up to eight low-impedance CDI coils, the CDI-8 effectively combines an 8 channel ignition expander with an 8 channel CDI module in one compact unit. The circuitry can reliably deliver 450 volt primary voltage at 15 000 RPM (or at 30 000 RPM for 4 cylinders). The output stages deliver up to 200 A into the CDI coil primary.

CDI rotary, single channel, twin channel, four channel, Porsche replacement

These units are designed for single and dual coil CDI applications using conventional distributed spark, or for rotary applications. More than 100 millijoules of energy is available per spark. The hardware is produced to operate reliably in this kind of condition in a racing environment.

Important note:

Newer versions of the single, dual and four channel CDIs are not direct plug-in replacements for the earlier versions; some wiring changes are required. Refer to the relevant datasheets or contact us for more information. See superseded CDI modules below.

CDI-8 Eight Channel

(MX00 Series Compatible)

Part No: #14004

CDI 8

8 Channel

(M1 Series Compatible)

Part No: #41015

CDI Twin Channel

Part No: #41010

CDI – Ignition Module for Porsche

Part No: #41018

Superseded CDI units

| Product | Details |

| Part No: #41004 | CDI single channel |

| Part No:#41009 | CDI single channel |

| Part No:# 41013 | CDI single channel |

| Part No: #41005 | CDI dual channel |

| Part No:# 41003 | CDI four channel |

| Part No:# 41011 | CDI four channel |

| Part No:# 41012 | CDI Rotary four channel |

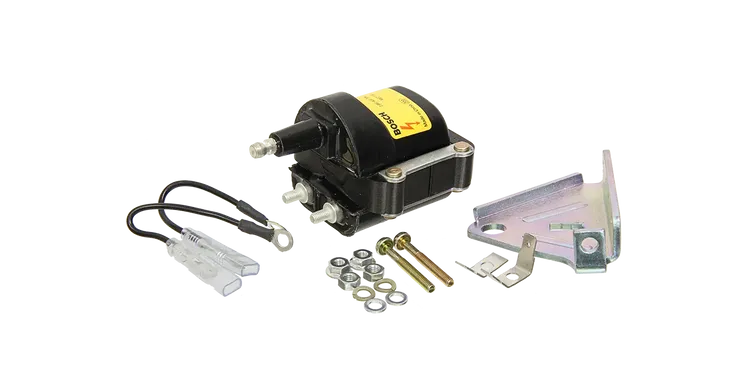

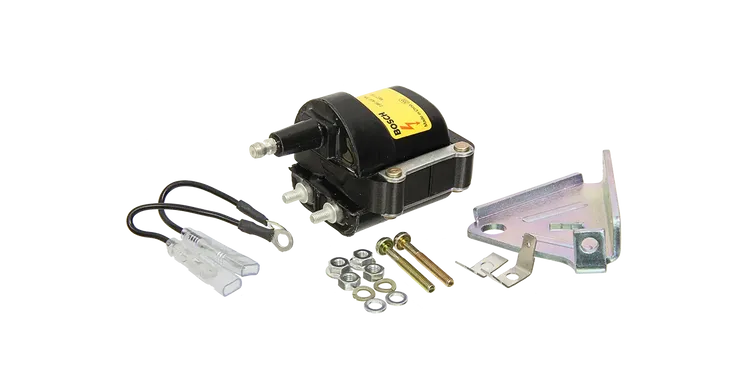

INDUCTIVE IGNITION COILS

Coils can be set up in different configurations—coil per cylinder, wasted spark or distributor. Choose an ignition coil compatible with the ignition mode in your application.

MEC718 Coil

Male end

Part No: #42001

MEC717 Coil

Female end

Part No: #42014

CDI COILS

Coils can be set up in different configurations – coil per cylinder, wasted spark or distributor. Choose an ignition coil compatible with the ignition mode in your application.

Mercury CDI coil

Part No: #42024

Cover for 2 CDI Coils

- Aluminium

Part No: #42025